مواصفة

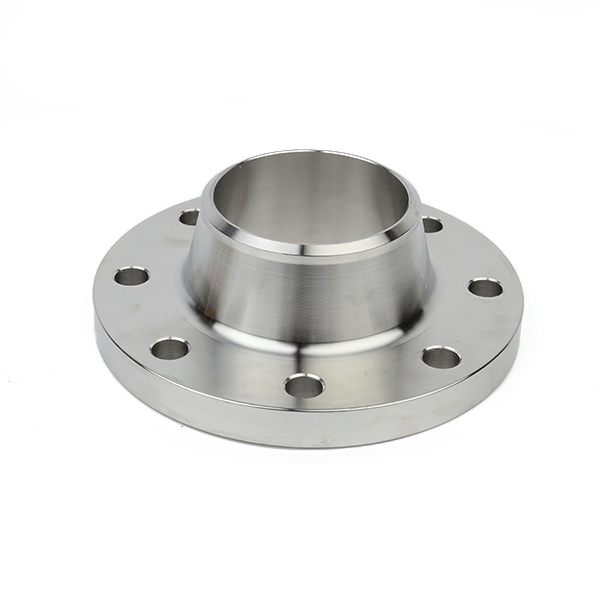

| اسم المنتج | وصلة تراكب/شفة مفكوكة |

| مقاس | 1/2"-24" |

| ضغط | 150#-2500#، PN0.6-PN400، 5K-40K |

| معيار | أنسي B16.5، EN1092-1، جيس B2220 الخ. |

| طرف أنبوبي | MSS SP 43، ASME B16.9 |

| مادة | الفولاذ المقاوم للصدأ:A182F304/304L، A182 F316/316L، A182F321، A182F310S، A182F347H، A182F316Ti، 317/317L، 904L، 1.4301، 1.4307، 1.4401، 1.4571، 1.4541، 254Mo وما إلى ذلك. |

| الفولاذ الكربوني:A105، A350LF2، S235Jr، S275Jr، St37، St45.8، A42CP، A48CP، E24، A515 Gr60، A515 Gr 70 إلخ. | |

| الفولاذ المقاوم للصدأ المزدوج:UNS31803، SAF2205، UNS32205، UNS31500، UNS32750، UNS32760، 1.4462، 1.4410، 1.4501 وما إلى ذلك. | |

| الصلب المستخدم في خطوط الأنابيب:A694 F42، A694F52، A694 F60، A694 F65، A694 F70، A694 F80 إلخ. | |

| سبيكة النيكل:إنكونيل 600، إنكونيل 625، إنكونيل 690، إنكولوي 800، إنكولوي 825، إنكولوي 800H، C22، C-276، مونيل 400، سبيكة 20 إلخ. | |

| سبيكة الكروم والموليبدينوم:A182F11، A182F5، A182F22، A182F91، A182F9، 16mo3،15Crmo، إلخ. | |

| طلب | صناعة البتروكيماويات؛ صناعة الطيران والفضاء؛ صناعة الأدوية؛ عادم الغازات؛ محطة توليد الطاقة؛ بناء السفن؛ معالجة المياه، إلخ. |

| المزايا | متوفر في المخزون، توصيل أسرع؛ متوفر بجميع المقاسات، قابل للتخصيص؛ جودة عالية |

معايير الأبعاد

عرض تفاصيل المنتج

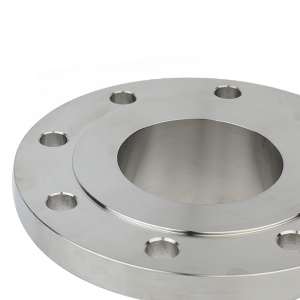

1. الوجه

يمكن أن يكون الوجه مرتفعًا (RF)، أو وجهًا كاملًا (FF)، أو مفصلًا حلقيًا (RTJ)، أو أخدودًا، أو لسانًا، أو حسب الطلب.

2. شطف الطرف وفقًا لمعيار ANSI B16.25

3. تشطيب دقيق باستخدام الحاسوب (CNC).

تشطيب السطح: يُقاس تشطيب سطح الفلنجة بمتوسط ارتفاع الخشونة الحسابي (AARH). ويُحدد هذا التشطيب وفقًا للمعيار المُستخدم. على سبيل المثال، يُحدد معيار ANSI B16.5 تشطيبات الأسطح ضمن نطاق 125AARH إلى 500AARH (من 3.2Ra إلى 12.5Ra). تتوفر تشطيبات أخرى عند الطلب، مثل 1.6 Ra كحد أقصى، أو 1.6/3.2 Ra، أو 3.2/6.3 Ra، أو 6.3/12.5 Ra. ويُعد النطاق 3.2/6.3Ra هو الأكثر شيوعًا.

وضع العلامات والتعبئة

• تستخدم كل طبقة غشاءً بلاستيكيًا لحماية السطح

• تُعبأ جميع منتجات الفولاذ المقاوم للصدأ في صناديق من الخشب الرقائقي. أما حواف الكربون ذات الأحجام الكبيرة فتُعبأ على منصات نقالة من الخشب الرقائقي. أو يمكن تخصيص التعبئة حسب الطلب.

• يمكن وضع علامة الشحن عند الطلب

• يمكن نقش أو طباعة العلامات على المنتجات. نقبل تصنيع المعدات الأصلية (OEM).

تقتيش

• اختبار UT

• اختبار اللياقة البدنية

• اختبار MT

• اختبار الأبعاد

قبل التسليم، سيقوم فريق مراقبة الجودة لدينا بإجراء اختبارات غير إتلافية وفحص الأبعاد. كما نقبل أيضًا فحص الطرف الثالث.

عملية الإنتاج

| 1. اختر مواد خام أصلية | 2. تقطيع المواد الخام | 3. التسخين المسبق |

| 4. التشكيل بالحدادة | 5. المعالجة الحرارية | 6. التشغيل الخشن |

| 7. الحفر | 8. التشغيل الدقيق | 9. وضع العلامات |

| 10. التفتيش | 11. التعبئة | 12. التسليم |

حالة تعاون

في مشروع بتركيا، تُستخدم الفلنجات في خطوط أنابيب الغاز الطبيعي. جميع هذه الفلنجات معتمدة من قبل شركة TÜV.

ورقة بيانات الشفة

1. يجب أن تكون أبعاد وتفاوتات الشفة وفقًا لمعيار ASME B16.5.

2. يتم إنتاج الفلنجات عن طريق التشكيل.

3. يجب أن تكون المواد وفقًا لمعايير ASTM A105 و ASTM A694 F65 و ASTM A694 F70.

4. يجب تبريد وتلطيف حواف ASTM A694 F65 و ASTM A694 F70.

5. يجب توفير شهادات اختبار المواد وتقارير المعالجة الحرارية لعمليات التفتيش من قبل جهات التفتيش الخارجية.

6. يجب أن تكون حواف WN ذات نهايات مشطوفة وفقًا لمعيار ASME B16.25.

7. يجب أن تكون قيم الاختبارات الكيميائية والميكانيكية للمواد (الصدم، الخضوع، الشد، إلخ) وفقًا للمعايير ذات الصلة.

8. يجب تشكيل جميع الأسطح وطلائها بزيت شفاف لمنع الصدأ.

9. يجب أن تتضمن العلامات المعلومات التالية،

• القطر (على سبيل المثال 6 بوصات)

• فئة الضغط (تتحمل حتى 150 رطلاً)

• درجة المادة (على سبيل المثال ASTM A 105)

• سمك الجدار (على سبيل المثال 4.78 مم)

• لا يُسخن (تاريخ انتهاء الصلاحية 138413)

• معيار الإنتاج (ASME B16.5)

10. يجب أن تكون المواد خالية من أي عيوب أو تشققات سطحية. يُمنع منعاً باتاً إجراء أي إصلاحات باللحام.

11. يجب أن تكون جميع الحواف ذات وجه مرتفع (RF) مع سطح مانع للتسرب. يجب أن يكون سطح منع التسرب Ra 3.2 – 6.3 ميكرومتر (125 – 250 ميكرومتر) وفقًا للمعيار ASME B46.1.

12. يجب تغليف المواد بطريقة تمنع حدوث أضرار لأسطح التشغيل والختم.

13. يجب أن تكون جميع الأبعاد ضمن نطاق التفاوتات الموجبة (+). يُمنع منعاً باتاً استخدام التفاوتات السالبة.

14. يجب أن تتم عملية شطف حواف الفلنجة وفقًا للمعيار ASME B16.25.

15. سيتم فحص عملية التصنيع في أي وقت بواسطة TPI.

16. يجوز لـ TPI أخذ عينات من أي مادة لإجراء اختبار كيميائي/ميكانيكي.

17. يجب مراجعة تقرير الفحص الوارد من قبل مفتش التفتيش الرئيسي.

| غرض | الحجم (بالبوصة) | فئة الضغط | CS | مادة | الوزن (مم) | موقع | الكمية |

| SORF | 12 | 150 رطل | 20 | A105 | - | حواف الخزانات | 48 |

| SORF | 8 | 150 رطل | 20 | A105 | - | حواف الخزانات | 32 |

| SORF | 3 | 150 رطل | 20 | A105 | - | حواف الخزانات | 32 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 2 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 4 |

| SORF | 20 | 150 رطل | 20 | A105 | - | حواف الخزانات | 6 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 16 | حواف الخزانات | 8 |

| SORF | 3 | 150 رطل | 20 | A105 | - | حواف الخزانات | 24 |

| SORF | 20 | 150 رطل | 20 | A105 | - | حواف الخزانات | 6 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 16 |

| غرض | الحجم (بالبوصة) | فئة الضغط | CS | مادة | الوزن (مم) | موقع | الكمية |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| شفة، رقبة ملحومة | 12 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| شفة، رقبة ملحومة | 12 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| شفة، رقبة ملحومة | 10 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| شفة، رقبة ملحومة | 6 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 4 |

| شفة، رقبة ملحومة | 4 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 4 |

| شفة، رقبة ملحومة | 18 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

| شفة، رقبة ملحومة | 8 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

| شفة، رقبة ملحومة | 8 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

التعليمات

1. ما هي الأنواع المختلفة لوصلات أنابيب الفولاذ المقاوم للصدأ؟

الإجابة: تشمل وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ وصلات الأنابيب الملحومة من طرف إلى طرف، ووصلات الأنابيب الملحومة من طرف إلى طرف، ووصلات الأنابيب الملولبة، والشفاه، والصمامات، وأنواع أخرى.

2. ما الفرق بين وصلات أنابيب الفولاذ المقاوم للصدأ 304 ووصلات أنابيب الفولاذ المقاوم للصدأ 316؟

ج: يُعدّ الفولاذ المقاوم للصدأ 304 مناسبًا لمعظم التطبيقات ويتميز بمقاومة ممتازة للتآكل. أما الفولاذ المقاوم للصدأ 316، فيتميز بمقاومة أفضل للتآكل في البيئات شديدة التآكل، وهو أنسب للتطبيقات البحرية والكيميائية.

3. ما هي فوائد استخدام وصلات الأنابيب الملحومة بالتشكيل؟

أ: توفر وصلات اللحام التناكبي المطروقة قوةً وموثوقيةً معززة، بالإضافة إلى وصلات مانعة للتسرب. كما أنها تتميز بمقاومة ممتازة للصدمات، وتُفضل استخدامها في التطبيقات ذات الضغط العالي ودرجات الحرارة المرتفعة.

4. ما هي شفة اللحام التناكبي؟

الإجابة: شفة اللحام التناكبي هي شفة أنبوب ذات محور مخروطي طويل، تُلحم بالأنبوب. توفر هذه الشفة انتقالًا سلسًا من الأنبوب إلى الشفة، مع قوة ومتانة ممتازتين.

5. ما هي درجة الفولاذ المقاوم للصدأ التي تُستخدم عادةً في وصلات الأنابيب؟

ج: تُستخدم درجات الفولاذ المقاوم للصدأ 304 و 316 و 304L و 316L و 317 بشكل شائع في وصلات الأنابيب نظرًا لمقاومتها الممتازة للتآكل ومتانتها وتعدد استخداماتها.

6. هل يمكن استخدام وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ في التطبيقات ذات درجات الحرارة العالية؟

الإجابة: نعم، وصلات الفولاذ المقاوم للصدأ مناسبة للتطبيقات ذات درجات الحرارة العالية. مع ذلك، يجب اختيار نوع الفولاذ المقاوم للصدأ المستخدم بعناية بناءً على متطلبات درجة الحرارة المحددة للتطبيق.

7. هل وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ مناسبة لصناعة الأغذية والمشروبات؟

الإجابة: نعم، تُستخدم وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ على نطاق واسع في صناعة الأغذية والمشروبات نظرًا لنظافتها ومقاومتها للتآكل وسهولة صيانتها.

8. ما الفرق بين وصلات اللحام المقبسية ووصلات اللحام التناكبي؟

الإجابة: في وصلات الأنابيب الملحومة بالوصلة، يتم إدخال الأنبوب في الوصلة ثم يتم لحامه لحامًا زاويًا لتوصيله. أما وصلات اللحام التناكبي، فتتطلب شطف أطراف الأنبوب ثم لحامها.

9. هل يمكن إعادة تدوير وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ؟

ج: نعم، وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ قابلة لإعادة التدوير بدرجة عالية. الفولاذ المقاوم للصدأ مادة مستدامة يمكن إعادة تدويرها واستخدامها دون أن تفقد خصائصها أو جودتها.

10. ما هي مزايا استخدام وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ مقارنة بالمواد الأخرى؟

أ: تتميز وصلات الأنابيب المصنوعة من الفولاذ المقاوم للصدأ بالعديد من المزايا، مثل مقاومتها الممتازة للتآكل، وقوتها العالية، ومتانتها، وخصائصها الصحية. كما أنها قليلة الصيانة، وتتمتع بعمر افتراضي طويل، ومظهر أنيق وجميل.

عرض تفاصيل المنتج

1. الوجه

يمكن أن يكون الوجه مرتفعًا (RF)، أو وجهًا كاملًا (FF)، أو مفصلًا حلقيًا (RTJ)، أو أخدودًا، أو لسانًا، أو حسب الطلب.

2. شطف الطرف وفقًا لمعيار ANSI B16.25

3. تشطيب دقيق باستخدام الحاسوب (CNC).

تشطيب السطح: يُقاس تشطيب سطح الفلنجة بمتوسط ارتفاع الخشونة الحسابي (AARH). ويُحدد هذا التشطيب وفقًا للمعيار المُستخدم. على سبيل المثال، يُحدد معيار ANSI B16.5 تشطيبات الأسطح ضمن نطاق 125AARH إلى 500AARH (من 3.2Ra إلى 12.5Ra). تتوفر تشطيبات أخرى عند الطلب، مثل 1.6 Ra كحد أقصى، أو 1.6/3.2 Ra، أو 3.2/6.3 Ra، أو 6.3/12.5 Ra. ويُعد النطاق 3.2/6.3Ra هو الأكثر شيوعًا.

وضع العلامات والتعبئة

• تستخدم كل طبقة غشاءً بلاستيكيًا لحماية السطح

• تُعبأ جميع منتجات الفولاذ المقاوم للصدأ في صناديق من الخشب الرقائقي. أما حواف الكربون ذات الأحجام الكبيرة فتُعبأ على منصات نقالة من الخشب الرقائقي. أو يمكن تخصيص التعبئة حسب الطلب.

• يمكن وضع علامة الشحن عند الطلب

• يمكن نقش أو طباعة العلامات على المنتجات. نقبل تصنيع المعدات الأصلية (OEM).

تقتيش

• اختبار UT

• اختبار اللياقة البدنية

• اختبار MT

• اختبار الأبعاد

قبل التسليم، سيقوم فريق مراقبة الجودة لدينا بإجراء اختبارات غير إتلافية وفحص الأبعاد. كما نقبل أيضًا فحص الطرف الثالث.

عملية الإنتاج

| 1. اختر مواد خام أصلية | 2. تقطيع المواد الخام | 3. التسخين المسبق |

| 4. التشكيل بالحدادة | 5. المعالجة الحرارية | 6. التشغيل الخشن |

| 7. الحفر | 8. التشغيل الدقيق | 9. وضع العلامات |

| 10. التفتيش | 11. التعبئة | 12. التسليم |

حالة تعاون

في مشروع بتركيا، تُستخدم الفلنجات في خطوط أنابيب الغاز الطبيعي. جميع هذه الفلنجات معتمدة من قبل شركة TÜV.

ورقة بيانات الشفة

1. يجب أن تكون أبعاد وتفاوتات الشفة وفقًا لمعيار ASME B16.5.

2. يتم إنتاج الفلنجات عن طريق التشكيل.

3. يجب أن تكون المواد وفقًا لمعايير ASTM A105 و ASTM A694 F65 و ASTM A694 F70.

4. يجب تبريد وتلطيف حواف ASTM A694 F65 و ASTM A694 F70.

5. يجب توفير شهادات اختبار المواد وتقارير المعالجة الحرارية لعمليات التفتيش من قبل جهات التفتيش الخارجية.

6. يجب أن تكون حواف WN ذات نهايات مشطوفة وفقًا لمعيار ASME B16.25.

7. يجب أن تكون قيم الاختبارات الكيميائية والميكانيكية للمواد (الصدم، الخضوع، الشد، إلخ) وفقًا للمعايير ذات الصلة.

8. يجب تشكيل جميع الأسطح وطلائها بزيت شفاف لمنع الصدأ.

9. يجب أن تتضمن العلامات المعلومات التالية،

• القطر (على سبيل المثال 6 بوصات)

• فئة الضغط (تتحمل حتى 150 رطلاً)

• درجة المادة (على سبيل المثال ASTM A 105)

• سمك الجدار (على سبيل المثال 4.78 مم)

• لا يُسخن (تاريخ انتهاء الصلاحية 138413)

• معيار الإنتاج (ASME B16.5)

10. يجب أن تكون المواد خالية من أي عيوب أو تشققات سطحية. يُمنع منعاً باتاً إجراء أي إصلاحات باللحام.

11. يجب أن تكون جميع الحواف ذات وجه مرتفع (RF) مع سطح مانع للتسرب. يجب أن يكون سطح منع التسرب Ra 3.2 – 6.3 ميكرومتر (125 – 250 ميكرومتر) وفقًا للمعيار ASME B46.1.

12. يجب تغليف المواد بطريقة تمنع حدوث أضرار لأسطح التشغيل والختم.

13. يجب أن تكون جميع الأبعاد ضمن نطاق التفاوتات الموجبة (+). يُمنع منعاً باتاً استخدام التفاوتات السالبة.

14. يجب أن تتم عملية شطف حواف الفلنجة وفقًا للمعيار ASME B16.25.

15. سيتم فحص عملية التصنيع في أي وقت بواسطة TPI.

16. يجوز لـ TPI أخذ عينات من أي مادة لإجراء اختبار كيميائي/ميكانيكي.

17. يجب مراجعة تقرير الفحص الوارد من قبل مفتش التفتيش الرئيسي.

| غرض | الحجم (بالبوصة) | فئة الضغط | CS | مادة | الوزن (مم) | موقع | الكمية |

| SORF | 12 | 150 رطل | 20 | A105 | - | حواف الخزانات | 48 |

| SORF | 8 | 150 رطل | 20 | A105 | - | حواف الخزانات | 32 |

| SORF | 3 | 150 رطل | 20 | A105 | - | حواف الخزانات | 32 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 2 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 4 |

| SORF | 20 | 150 رطل | 20 | A105 | - | حواف الخزانات | 6 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 16 | حواف الخزانات | 8 |

| SORF | 3 | 150 رطل | 20 | A105 | - | حواف الخزانات | 24 |

| SORF | 20 | 150 رطل | 20 | A105 | - | حواف الخزانات | 6 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 5.54 | حواف الخزانات | 8 |

| شفة، رقبة ملحومة | 24 | 150 رطل | 20 | A105 | 14 | حواف الخزانات | 16 |

| غرض | الحجم (بالبوصة) | فئة الضغط | CS | مادة | الوزن (مم) | موقع | الكمية |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| شفة، رقبة ملحومة | 12 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| شفة، رقبة ملحومة | 20 | 400 رطل | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| شفة، رقبة ملحومة | 12 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| شفة، رقبة ملحومة | 24 | 400 رطل | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| شفة، رقبة ملحومة | 4 | 400 رطل | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| شفة، رقبة ملحومة | 10 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| شفة، رقبة ملحومة | 6 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 4 |

| شفة، رقبة ملحومة | 4 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 4 |

| شفة، رقبة ملحومة | 18 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

| شفة، رقبة ملحومة | 8 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

| شفة، رقبة ملحومة | 8 | 300 رطل | 51 | ASTM A694 F65 | 4.78 | رابغ | 2 |

تُعدّ وصلات الأنابيب مكونات أساسية في نظام الأنابيب، وتُستخدم للتوصيل، وإعادة التوجيه، والتحويل، وتغيير الحجم، والإحكام، أو التحكم في تدفق السوائل. وتُستخدم على نطاق واسع في مجالات مثل البناء، والصناعة، والطاقة، والخدمات البلدية.

الوظائف الرئيسية:يمكنه أداء وظائف مثل توصيل الأنابيب، وتغيير اتجاه التدفق، وتقسيم ودمج التدفقات، وضبط أقطار الأنابيب، وإحكام إغلاق الأنابيب، والتحكم والتنظيم.

نطاق التطبيق:

- إمدادات المياه والصرف الصحي للمباني:تُستخدم وصلات PVC على شكل حرف U ووصلات PPR ثلاثية في شبكات أنابيب المياه.

- خطوط الأنابيب الصناعية:تُستخدم حواف الفولاذ المقاوم للصدأ ومرفقات الفولاذ السبائكي لنقل المواد الكيميائية.

- نقل الطاقة:تُستخدم وصلات أنابيب الصلب عالية الضغط في خطوط أنابيب النفط والغاز.

- أنظمة التدفئة والتهوية وتكييف الهواء (HVAC):تُستخدم وصلات الأنابيب النحاسية لتوصيل خطوط أنابيب التبريد، وتُستخدم الوصلات المرنة لتقليل الاهتزاز.

- الري الزراعي:تسهل الموصلات السريعة عملية تجميع وتفكيك أنظمة الري بالرش.

-

وصلات أنابيب من الفولاذ الكربوني A105 فئة 150 Ss...

-

شفة فتحة الضغط القياسي المصنوعة من الفولاذ المقاوم للصدأ المطروق...

-

رقبة لحام من الفولاذ الكربوني من النوع 6 بوصة ANSI CLASS...

-

شفة فولاذية كربونية A105 مطروقة مغلقة BL

-

ASTM A182 F51 F53 BL ANSI B16.5 الفولاذ المقاوم للصدأ...

-

شفة فتحة WN 4 بوصة 900# RF A105 مزدوجة الصنف...